Mastering the Complexity of Blending Metals: A Recipe for Success

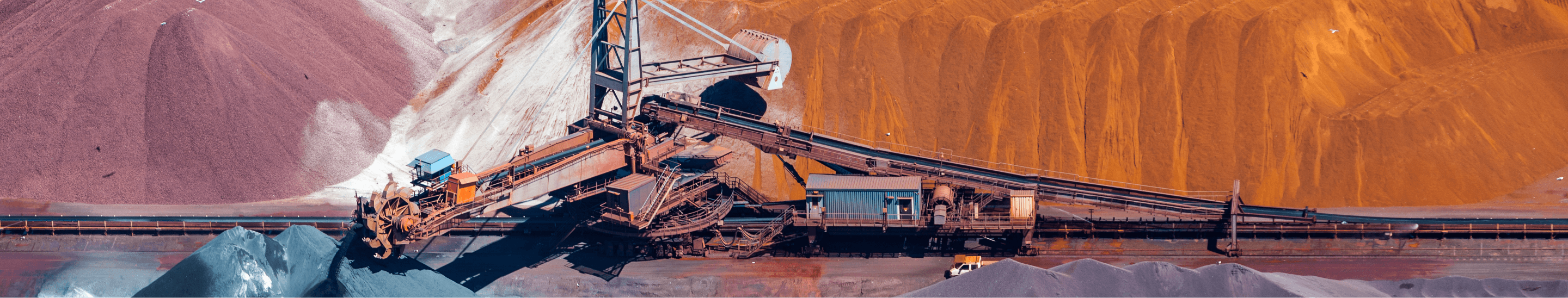

In the world of mining and resource extraction, companies must balance operational efficiency, financial goals, and sustainability. This is challenging given the variability of metal assays, introducing uncertainty in resource estimation and production planning.

In this landscape, blending optimization offers a significant opportunity to uncover value from within your operations. However, the process is complex, requiring precision. Finding the optimal blend involves various processes, variable recovery factors, and shifting constraints. At the same time, balancing supply, storage, throughput, and product quality is crucial.

The uncertain nature of assays further complicates the process, necessitating the ability to adapt production plans quickly. This is why robust planning software is essential for maintaining plan value amidst assay deviations. Optimally mixing metals is not just important, but essential for continued success.

Achieving consistency and quality

One of the primary reasons for optimally mixing metals is to ensure the consistency and quality of products. When dealing with a wide range of metals, you have to consider each one with its unique properties and specifications. Blending them to precise standards allows you to meet customer requirements consistently. Steady product quality is crucial in industries like aerospace, electronics, and automotive where even minor variations in metal quality can lead to significant problems.

Meeting regulatory standards

Compliance with stringent environmental and safety regulations is paramount in the mining industry. Since you can’t control the grade of extracted materials, optimally mixing metals enables you to control the composition of final products, ensuring you meet or exceed all necessary standards. You avoid the risk of penalties and or producing off-specification products that could lead to costly reprocessing. This not only safeguards the environment but also maintains your company’s social responsibility, a factor of increasing importance in today’s world.

Maximizing economic efficiency

Efficiently blending metals can lead to significant cost savings. The intricacy of the process involves many considerations such as variations in ore grade or feed mix, production capacity, and environmental impacts, among others. By achieving the desired material composition with precision, you reduce waste and minimize the need for additional processing steps. When you also have decisions involving inventory and logistics, the operational complexity exponentially grows. However, this presents further opportunity for efficiency gains, reducing operational costs, and minimizing your environmental footprint.

Tailoring metals to market demand

The market for metals and minerals is dynamic, with changing customer demands, specifications, and emerging market trends. Optimal blending maximizes mix quality, giving you the flexibility to adjust production to a volatile market. You can also tap into new opportunities and accommodate market shifts, such as the push towards cleaner energy and the recent investment in critical metals such as lithium. This agility allows you to respond swiftly, maintain competitiveness, and secure your position in a rapidly changing industry.

Reducing environmental impact

During the COP28 Global Stocktake, the UN Secretary-General Antonio Guterres stressed the importance of extracting and processing critical metals in a sustainable, fair, and just way for the clean energy revolution. Optimal blending significantly lowers waste and energy consumption to further reduce the environmental impact of your operations. In addition to contributing to your overall sustainability efforts, you improve your company image and reduce the risk of regulatory penalties.

Fostering innovation

In this competitive industry, innovation is key to staying ahead. Optimally mixing metals demands continuous improvement, driving innovation in techniques and technologies throughout production, storage, and distribution processes. This not only enhances your operational efficiency but contributes to securing a leadership position in the industry.

Case study: tackling planning complexities of feed mix to maximize profits

Glencore, a global leader in mining and commodities trading, partnered with The Logic Factory to implement integrated planning in their zinc and lead operations. The solution has optimized decision-making, increasing efficiency and flexibility. Read the full story here.

Partnering for blending optimization and supply chain excellence

Blending optimization is far from a mundane task, it is a strategic imperative. It forms the foundation for consistent product quality, regulatory compliance, operational efficiency, and environmental sustainability. In an industry as competitive and dynamic as mining, mastering metals blending is a significant ingredient in the recipe for success.

It’s not easy to manage such complexity and find the best solution in a sea of endless possibilities, but it can be done. The Logic Factory consultants are here to support you on the path to blending optimization, so you can not only meet but exceed customer expectations while advancing towards a more sustainable and innovative future.